Downhole motor is a kind of downhole dynamic drilling tool drove by the hydraulic power of drilling mud, and its core power part is a positive displacement motor. The tool is with simple structure, convenient operation and reliable performance. The tool can be drove by the power fluid, such as oil-based mud, emulsion mud and clay mud, is adaptable and flexible, and can be applied to horizontal wells, cluster wells particular drilling operations, that can greatly increase the drilling speed and economic benefits.

Compared with the traditional turntable driven drill pipe drilling operations, downhole motor is with many advantages as following:

■ The drilling fluid input flow is proportional to the downhole motor output speed.

■ Downhole motor output torque is linearity relation with pressure loss produced by drilling fluid through the motor.

■ Downhole motor rotary power is only used to drive the drill bit to reduce the drill pipe wear, streamline operations, improve drilling accuracy, and saving drilling power.

■ Lower downhole motor output speed, greater torque, and longer net drilling time.

■ Downhole motor is adopted a group of multi-column thrust radial ball bearing, resistance to high pressure, and high penetration rate.

■ Downhole motor is adopted insert welded tungsten carbide transverse bearing, long service lift.

■ Pressure loss of drill bit nozzle is up to 7.0MPa, high horsepower of drill bit hydraulic, rinse drill bit clean to prevent drill bit balling.

Downhole motor is a kind of downhole dynamic drilling tool drove by the power of drilling mud. Mud stream from the outlet of mud pump flows through a by-pass valve into the motor. This stream produces pressure loss at both inlet and outlet of the pump, to push the rotor into rotating, and to transmit the torque and speed onto the bit. The downhole motor property mainly depends upon its property parameters.

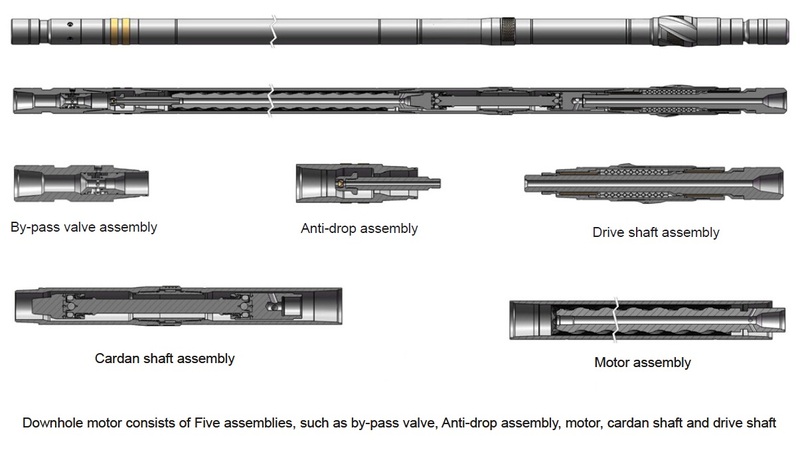

Construction

By-pass valve assembly

It has two positions of by-pass and close (Fig.2). It is in by-pass position during trip operation, circulates mud fluid in the drill string into the annular space by-passing the idle motor, so that no mud may spray out onto the platform during the trip operation. When mud flow rate and pressure reach the setting value, the valve stem moves down and closes the valve. Meanwhile, mud stream flows through the motor, and converts the pressure energy into mechanical energy. As mud flow rate is too low, or mud pump stops, and as the created pressure is not enough to overcome spring force and static friction force, the spring presses the stem upward, and by-pass valve is in open position.

Motor assembly

It consists of stator and rotor. Stator is made by squeezing rubber sleeve on the inner wall of steel tube. Rubber sleeve inner hole forms spiral structure with a certain geometric parameter. Rotor is a screw rod with chrome-plated layer.

Stator and rotor matches with each other, to form spiral line and seal cavity through their lead difference. With rotor running in the stator, the seal cavity is moving along its axial direction, continuously forms and disappears, to complete its energy conversion. This is the basic principle of downhole motor.

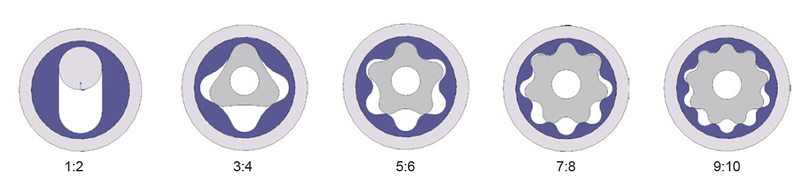

Spiral seal line on rotor is divided into single end and multi-end (stator with one more end than rotor). The less ends the motor has, the higher speed and the lower torque are. The more ends it has, the lower speed and the higher torque are. Fig.3 shows the sectional profile of several typical motors.

A lead forms a seal cavity in motor stator. This is called one stage. When the rated working pressure of each stage lows down to 0.8 Mpa, the maximum pressure loss will be 1.3 times of the rated pressure. For an example, for 4-stage motor, the rated pressure loss shall be 3.2 Mpa, the maximum pressure loss shall be 4.2 Mpa. As the pressure loss is over such value, motor may bring about leakage and speed will quickly slow down. More seriously, it may cause operation into complete stop, even cause the motor to be damaged. This is the caution for the customers.

In order to ensure rotor seal in good condition, the matching size between rotor and stator relates closely to depth temperature. Therefore, correct downhole temperature shall be provided to the manufacturer for reliable selection of appropriate motor. The actual mud flow rate is required in the recommended range. Otherwise incorrect flow rate may affect the motor efficiency, even cause speeding up motor wear.

Motor output torque is proportional to its pressure loss, but its outlet speed is inversely proportional to mud flow rate. With load increasing, drill tools speed decreases. Thus, pressure shall be controlled by the pressure gauge and flow rate shall be controlled by the flow rate gauge on surface. This way may control both torque and speed of downhole drill tools.

Cardan shaft assembly

The function of cardan shaft is to convert planetary motion into fixed constant rotation of drive shaft, to transmit torque and speed from motor on the drive shaft, and to the bit. Cardan shaft mostly use flat shaft, but some are flexible shafts.

Our flat type shaft used on downhole motor is made by linear cutting technology. So the cut has high parallelism, roughness can reach Ra 6.3, and it doesn’t damage metal chemical composition. Thus, it has longer running life and less mechanical loss.

Ball drive cardan shaft transfer torque by ball, rod, and twisted connection. Friction pair is lubricated with high temperature grease, and the ball moving parts are sealed by rubber sleeve to isolate grounding-type drilling fluid. The working surface of ball drive cardan shaft is carried out with special surface treatment to increase the hardness and high-temperature resistance relatively; therefore, wear resistance and reliability will be further improved, and the working life is extended accordingly.

Downhole motor shall be disassembled as quickly as possible after use to examine cardan shaft. If it is found out that wear degree is over maintenance standard, relevant consumable components shall be changed promptly. If it is not, downhole motor can not be running normally due to over run time of cardan shaft.

Drive shaft assembly

Drive shaft is to transmit motor rotary dynamic force onto the bit, meanwhile to withstand axial and radial load from drilling weight. We have two types of drive shafts, as follows:

1) Bit nozzle pressure loss is 7.0 Mpa, using hard alloy radial bearing and drive shaft assembly with thrust bearings (Fig.6);

2) Bit nozzle pressure loss is 14.0 Mpa, using hard alloy radial bearing and PDC cutter flat thrust bearing. It has longer lasting life and higher bearing capacity.